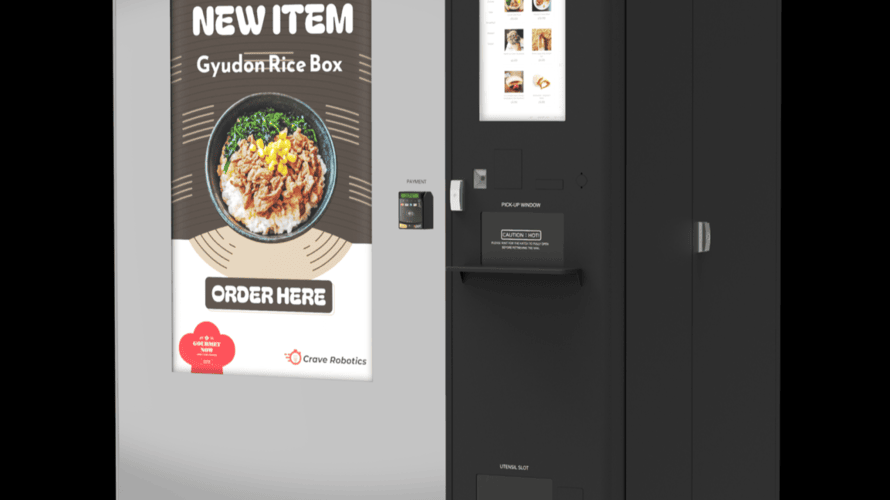

Crave Robotics, a leader in autonomous food vending solutions, today announced the launch of its fundamentally redesigned hot food vending kiosk, the CraveBot™ Ultra. This next-generation machine is now fully UL Listed, signifying its compliance with rigorous safety and performance standards, and setting a new benchmark for stability and durability in the automated retail industry.

Image Source: Crave Robotics

The company emphasized that the Cravebot™ Ultra is not a minor update but a complete re-engineering of the machine’s core architecture, sharing only external aesthetic similarities with its predecessor.

“The CraveBot™ Ultra represents a dramatic leap in engineering safety and operational stability for the hot food vending space,” said Paul Chen, CEO of Crave Robotics, in a recent press release. “We understood that achieving the UL listing required more than just replacing a few parts. We built a fundamentally different machine from the ground up, ensuring every component meets the highest safety standards while delivering unparalleled longevity for our operators.”

Re-Engineered Core for UL Compliance and Reliability

The most significant changes in the CraveBot™ Ultra are beneath the surface, ensuring the kiosk is compliant with strict UL (Underwriters Laboratories) standards and ready for seamless NAMA (National Automatic Merchandising Association) acceptance.

Key Technical Overhauls Include:

- New Control System: A completely different, modern control system replaces the legacy hardware, offering superior fault monitoring and safety interlocks.

- Electrical Safety & Layout: The specifications of all electrical components and the layout of signal wires have been re-engineered to meet stringent UL requirements for spacing, protection, and fire hazard mitigation.

- Enhanced Protection: Protection and spacing of related electrical and mechanical parts have been dramatically improved to increase operational safety and prevent component failure.

Increased Durability: Built to Last

While the electrical changes are not visible to the end-user, Crave Robotics focused on durability enhancements that directly benefit the operator and the consumer, leading to extended uptime and a significantly more stable machine.

- Metal Chains for Longevity: Plastic drive belts within the vending mechanism have been replaced with high-strength metal chains, drastically improving longevity and resistance to wear and tear.

- Improved Rotary Mechanism: The core rotary mechanism has been reinforced and improved to be more resistant to damage, minimizing service calls.

“The consumer will find the certified Carvebot™ Ultra to be noticeably more durable, even if they don’t see the new control board,” added Chen. “The combined effect of all these changes—from the heavy-duty metal chains to the new electrical controls—is a machine defined by stability and reliability, ensuring our clients can serve hot, quality food 24/7 without interruption.”

The company is now positioned to submit its comprehensive certification reports for rapid evaluation and compliance with NAMA standards, facilitating broader deployment across highly regulated locations like corporate offices, airports, hospitals, and universities.

About Crave Robotics

U.S.-based Crave Robotics is dedicated to developing automated solutions that bring convenience and quality to the food service industry. Through cutting-edge robotics and safe, certified hardware, Crave Robotics empowers businesses to offer hot, freshly prepared meals around the clock, improving accessibility and customer satisfaction. To learn more, visit craverobotics.co.