Royal Vending Installs Automated Warehouse Picking To Manage Fast Growth

Fast growth is a problem most business owners want to have, but Ryan Harrington, owner of Royal Vending in Portland, Ore., didn’t want to let it get the best of him. While the company was growing fast, Harrington wanted to make sure his existing customers continued to receive the same quality of service they were used to.

Fast growth is a problem most business owners want to have, but Ryan Harrington, owner of Royal Vending in Portland, Ore., didn’t want to let it get the best of him. While the company was growing fast, Harrington wanted to make sure his existing customers continued to receive the same quality of service they were used to.

This year, Royal Vending, which was recently recognized as one of the country’s fastest growing private firms by the Inc. 5000, hired its first operations manager, Mike Levi.

Levi spearheaded the introduction of the LightSpeed Automation warehouse picking system, which has improved the efficiency of the company’s warehouse, ensuring the timeliness and accuracy of the company’s deliveries to its 375 vending machines and 75 micro markets.

An efficient warehouse picking system is crucial to a refreshment service company’s ability to serve its customers. As the company added more accounts, Harrington felt it was time for an automated warehouse picking system.

“We weren’t using a software system to pick with,” Harrington said. “We were basically running two separate picking systems and two separate pieces of paper being printed out for our warehouse pickers.”

There were separate picking systems for the vending and micro market deliveries.

“Mike came on board and put all of those systems together through LightSpeed Automation,” Harrington said. “That enabled us to not have two separate systems in the warehouse and bring it all under one umbrella.”

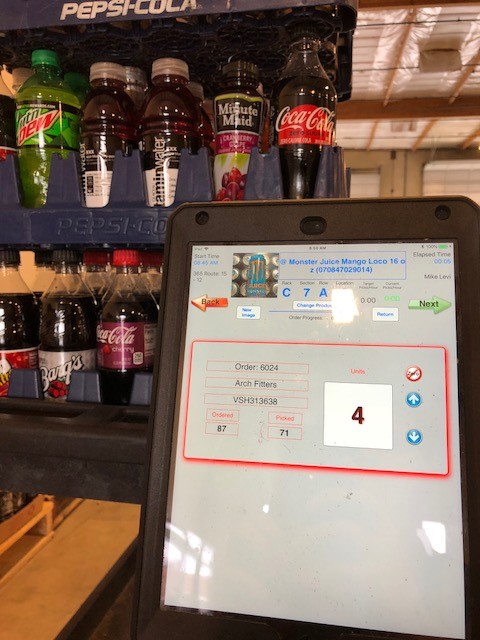

The LightSpeed Automation system has allowed the pickers to pick using the touchpads and graphic displays on their iPads, which was easier than using a printed list that required them to cross out lines on a pick list. Instead, the iPad directs the picker from item to item in the warehouse, enabling them to pick several orders at a time. The system prompts the picker to confirm each item before moving to the next one.

The LightSpeed Automation system has allowed the pickers to pick using the touchpads and graphic displays on their iPads, which was easier than using a printed list that required them to cross out lines on a pick list. Instead, the iPad directs the picker from item to item in the warehouse, enabling them to pick several orders at a time. The system prompts the picker to confirm each item before moving to the next one.

The system also tracks the picker’s progress as they log in and out on theiPad, generating management reports. The system also optimizes the route the picker follows in the warehouse.

Having a single picking system for both vending and micro market accounts is more efficient, even for a company such as Royal Vending that has separate routes for vending and micro market deliveries.

“We saw LightSpeed as an opportunity to have this iPad that actually has a picture of the product, so really anybody could match up the photo of that product with the actual product on our wall,” Harrington said.

Levi said the total daily picking time has been cut in half to four hours a day. Mispicks have also been reduced.

The LightSpeed system was easy for the pickers to learn, Levi said. It is especially easy for new employees.

“There’s zero room for error regarding which item you’re selecting,” Levi said, thanks to the picture of the product on the iPad.

The office staff is no longer exporting the pick tickets to Microsoft Excel spread sheets, then sorting the tickets by item before giving them to the pickers. In addition, out of stocks and shorts required additional updates. The automated system has eliminated all of this.

The office staff is no longer exporting the pick tickets to Microsoft Excel spread sheets, then sorting the tickets by item before giving them to the pickers. In addition, out of stocks and shorts required additional updates. The automated system has eliminated all of this.

The number of pickers in the warehouse has not declined since introducing LightSpeed Automation, but that’s only because the company has added an additional $1 million worth of business this year.

There are now two full time pickers in the warehouse. Only a few more hours have been added to the warehouse labor to accommodate this growth.

“It’s definitely responsible for keeping us profitable through the growth,” Harrington said. He expects in the near future they will be adding as many as two more pickers, based on the current growth rate.

“We really don’t have to do any upgrade to our system at this point to do that,” he said. “We’ve paid for it at least five times by now,” he added, due to increased productivity and fewer errors.

Royal Vending is somewhat unique in that it has pre-kitted its deliveries from its foundation. Harrington used Microsoft Excel in the beginning to organize his totes.

“We created a pick ticket so that the truck was loaded with the amount of product that we thought it needed,” he said. “We were just guessing.” The truck would return between a quarter and a half full.

The company continues to rely on its Parlevel vending management system for managing its vending business and the 365 Retail Markets software for its micro market business.

The company will consider adding the LightSpeed Automation pick-tolight system when it grows to more than 10 pickers in the warehouse, Harrington said.

By Jeff Adair, Editor

![]() Vending Technology News | More News | Vending Newsletter sign up | Questions? Contact us | email press release

Vending Technology News | More News | Vending Newsletter sign up | Questions? Contact us | email press release

Also see: Software Companies | Technology Companies | Micro Markets | Cashless Vending | Distributors | Classified Ads | Home |

VENDING YELLOW PAGES DIRECTORIES:

Call us at 1-800-956-8363, POST YOUR COMPANY