Arkansas Operator Shows How Technology Can Empower A 1-Route Vending Business

Gone are the days when a vending operator needed to have multiple routes to justify investing in new technology. Advantage Vending and Coffee Services, a 1-route operation in Searcy, Ark., utilizes vending management software (VMS), telemetry and cashless acceptance, and is expanding into micro markets.

Gone are the days when a vending operator needed to have multiple routes to justify investing in new technology. Advantage Vending and Coffee Services, a 1-route operation in Searcy, Ark., utilizes vending management software (VMS), telemetry and cashless acceptance, and is expanding into micro markets.

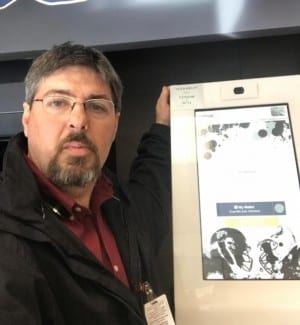

Under the leadership of owner Mike Kever, the company’s technology quest began several years ago when he began investing in cashless readers.

In 2014 he deployed VMS to gain the efficiencies of dynamic routing based on pre-kitting and remote inventory management.

Kever bought the company in 2004 after working as an employee for four years. At the time he bought the company, the route truck carried a large amount of inventory, and the driver would pull product from the truck after going to the machines to see what was needed. “We had to keep a lot more product on hand, and keeping track of that was very difficult,” Kever said.

Kever knew that vending software was advancing. “I knew there was a better way to do it than the way we were doing it,” he said. “But everything out there (in 2008) was outrageously expensive.”

After experimenting with some custom software, he was not satisfied with the results.

Three years ago, he attended the National Automatic Merchandising Association OneShow specifically to explore VMS offerings. “I wanted to get a better idea what was out there,” he said.

VMS Makes An Impression

Kever was favorably impressed with the Parlevel VMS system. “They were a young company at the time,” he said. “I thought that was beneficial because I thought they would be eager, and they were, and still are.” He was impressed by the fact that Parlevel sent someone out to his company to provide instruction.

“Parlevel was the only company that offered to send somebody to our facility and help us get implemented,” he said. Parlevel worked with him for three months to deploy the VMS.

Kever reorganized the warehouse to be able to pre-kit the machines. He deployed the pre-kitting six months after meeting Parlevel at the NAMA show.

During the first six months after the VMS implementation, the company was able to reduce machine service visits, reduce inventory on the truck and increase its sales.

The Parlevel VMS provides real-time access to machine inventory, automatically displays sales per item, and creates a pre-kit list. The company can adjust product quantities as necessary before the pre-kit order is issued.

Efficiency Improved By At Least 25 Percent

“We’ve increased our efficiency by at least 25 percent, if not 30,” Kever said. “Between adding to the number of machines and stretching some machines (service visits) out farther so that your collects are higher when you get there, I’d say it’s 25 or 30 percent,” he said.

The hardest part for the driver was learning to use iPads for record keeping.

The pre-kitting and the dynamic routing has allowed the company to service more accounts in the same number of service visits. As a result, the company has been able to add accounts without having to add labor.

The truck inventory is now 30 percent of what it was prior to pre-kitting. The truck now services an additional 40 percent more machines – 120 machines in about 70 locations.

Dynamic scheduling has reduced average service from every 10 days to every 14 days.

“Where I gained efficiencies is not necessarily in the number of times we were stopping – it was really about being able to put more machines on one driver,” he said.

“We can move products out much faster,” he added. “It’s much easier to change product.” This is because the machine- and item-level data allows him to see how well the individual stock keeping units (SKUs) are moving.

“I have far more control of my inventory, as far as do I need to order more or less,” he said.

It used to take him six months to evaluate a product’s performance. With Parlevel’s software, he can sometimes know in 30 days if he will keep a product in the machines, he said, “because of the analytics that are available to me.”

Without the VMS, “At the very least, I would have to have my part-time (warehouse worker) working full-time,” he said. “What I spend in VMS (for the monthly subscription fee) would probably cost me twice that much in labor, at least.”

Dynamic Routing In A Rural Market

“The dynamic routing was beneficial,” he said. This is especially true for a company serving a rural area. “It’s very important for us because we’re very spread out,” Kever said. Locations are spread out across large distances, making service costs high in relation to revenue. Some of the accounts are 40 to 45 minutes away from the warehouse – in different directions.

For machines that are not DEX capable – which account for about a third of the company’s machines – the company forecasts machine inventory levels based on historical averages. For these machines, the company uses the average sales for 10 service visits. “It gives us a pretty good forecast so we can still pre-kit and route those stops in with our other stops,” he said.

The truck still returns to the warehouse with some product. “We’re still keeping a certain amount of inventory on it,” Kever said.

Telemetry And Cashless: Hand-In-Hand

The company’s DEX-capable machines have USA Technologies ePorts that automatically send the data three times a day. The driver also inventories the machine using his iPad when he services the machine.

Kever installed the ePorts as part of a cashless rollout that occurred around the same time he was exploring VMS technology.

Advantage Vending and Coffee Service was one of Parlevel’s earliest customers, and Parlevel did not have a telemetry device at the time Kever was looking to deploy Parlevel’s VMS system.

“We were already installing (USA Technologies ePorts) when we implemented the Parlevel (software),” he said. “It (the ePorts) just physically came first. Physically, we got all of our telemeters and cashless devices and had all the telemeters installed before we implemented the VMS. Parlevel downloads the information from USA Technologies’ (ePorts).”

The company has 30 cashless readers and plans to add 20 more this year.

Cashless Keeps Growing

“The threshold for adding cashless has dropped considerably over the last two or three years,” Kever said. “When I (first) installed, their recommendation was about $70 a week per machine to add cashless. I think the threshold is about $40 now.” This is because of the sales increase that cashless capability can deliver.

VMS Also Supports Micro Markets

The company would have reduced the number of SKUs it inventories as a result of the pre-kitting, if it were not for the fact that around the same time, it also expanded into micro markets. Micro markets require more SKUs.

It was the capability of the VMS that encouraged Kever to expand into micro markets. “It seemed like a natural fit,” he said. The micro market module is part of the Parlevel VMS.

The investment in technology has allowed the company to grow without having to add additional labor.

At present, there is one full-time driver and a part-time pre-kitter. Kever, in addition to running the company, services the two micro markets that the company recently added. His wife, Jantha, handles the OCS deliveries, which represent 15 percent of the total business.

Advantage Vending and Coffee Services has proven that vending technology can deliver significant benefits to a 1-route vending operation, (501) 368-8363.

For more information about Parlevel Vending Management Software: parlevelsystems.com.

![]() Vending Technology News | More News | Vending Newsletter sign up | Questions? Contact us | email press release |

Vending Technology News | More News | Vending Newsletter sign up | Questions? Contact us | email press release |

Also see: Software Companies | Technology Companies | Micro Markets | Cashless Vending | Distributors | Classified Ads | Home |

VENDING YELLOW PAGES DIRECTORIES:

Call us at 1-800-956-8363 to POST YOUR COMPANY, or QUESTIONS?